An Educational Platform for Systems and Control - Theory and Practice.

The complex and highly mathematical nature of control theory can make the subject difficult for students to grasp. Existing commercial systems for teaching control theory are expensive, at times difficult to use, and not conducive to unsupervised learning. Our SimplePID Training System addresses these issues by providing an affordable, user-friendly, and comprehensive educational tool for control theory and practice.

SimplePID - A quick overview

The SimplePID Control System has been designed to provide students and instructors with a platform to investigate the behaviour of a physical system when controlled using various forms of proportional, integral and differential control. The system is highly visual, simple to operate and yet lends itself to standard analysis techniques such as root locus analysis.

The system (developed at the School of Mechanical and Manufacturing Engineering, DCU), is designed to instruct trainee engineers and scientists in the theory and application of PID control strategies. It features a ball suspended in an air stream, the position of which depends upon fan speed and controller settings. This hardware is compatible with a Windows PC and is supplied with control software, numerical modeling code and comprehensive teaching materials.

SimplePID - Four Stage Educational Approach

Modeling

Students formulate a theoretical model to describe the movement of the ball. This model can then be included in the numerical code describing the overall system..

2. System Identification

Before running the code, it is necessary to perform system identification to quantify physical parameters of the system. This is conducted in the laboratory. The numerical model can then be compared to experimental results to refine parameters in the code

3. Numerical Simulation

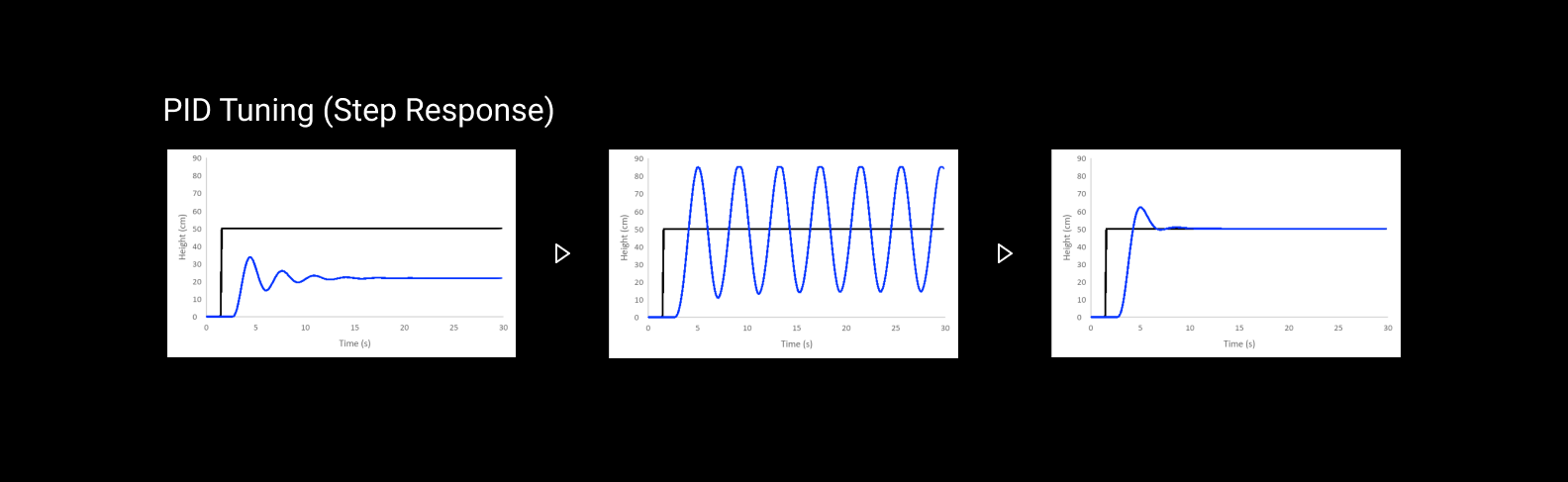

When simulating the response of the system using a suitably accurate model, students can implement various forms of PID control and discover the effects of proportional, integral and derivative control gains. This analysis can be further enhanced by performing a root locus analysis, a Routh Hurwitz stability analysis and a determination of steady state error. Students are then tasked with tuning the system for optimum performance

4. Applied Control

The second laboratory session allows students to implement various forms of control on the physical rig. In this stage, students can compare their experimental results to those obtained previously from simulations.

Software

SimplePID includes:

Windows based software (requires Windows 8 or later) for apparatus control and data storage.

Opensource Scilab Xcos numerical models (Instructor and Student version).

Numerical models may be carried out using open source Scilab Xcos software corresponding to stage 3 (above) - Numerical Simulation.

A numerical model developed in Xcos is supplied with the apparatus. Students are required to finish the model by specifying the transfer function developed in stage 1 - Modeling and by parameterising the model following stage 2 - System Identification.

Students can develop various control strategies in the simulated environment and then assess their suitability on the physical system in stage 4 - Applied Control.

Course Manuals

An assignment manual is included providing clear instructions for students. To complete the assignment students will typically be required to perform two laboratory sessions using the physical rig in addition to conducting analysis and numerical simulation.

The laboratory sessions combined with the required analysis as specified in the documentation will reinforce theoretical concepts typically covered in an introductory control course.

Courseware

Introduction

Transfer Functions

Simulation

Measured Values

Experimental Results Using Proportional Control

Simulation Using Proportional Control

Simulations Using Various Control Strategies

Root Locus Analysis

Routh Hurwitz Analysis

Simulated Response in Unstable Regime

Steady State Error

PID Tuning

Experimental Results